EDITOR’S NOTE: Steven A. Jaasund, P.E. is Geoenergy Senior Product Manager for LDX Solutions. He was a co-owner of Geoenergy® and regularly provides his expertise to leaders in the pulp and forest products industry. Jaasund can be reached at sjaasund@ldxsolutions.com

Введение

This article will provide a framework of understanding the processes that set the stage for

emission control design. Areas of focus include the following:

- Combustion basics

- Particle formation and behavior

- Gaseous emission characteristics

This is the second part of a three part series. Please note, this three part series will not focus on carbon monoxide. Part one of this three part series covered combustion basics – the formation of liquids, solids, and gases during combustion. Here, in part two, the discussion will focus on particle formation and behavior.

Particle Formation and Behavior

A micron, also known as a micrometer (represented as μm), is equal to one millionth of a meter. Human hair is 50 to 70 microns (or micrometers) in diameter. This is about 30 times larger than the largest fine particle. Fine particles are less than 2.5 microns in diameter. Ultrafine particles are less than .1 microns in diameter. Ultrafine particles are not visible under a microscope.

Particle Origin Defines Size

A particle’s origin will define its size. As a general rule, thermally and chemically created particles tend to be less than 1 micron in size. These particles can be observed as smoke, blue haze, and fumes. There are some exceptions but in most instances the rule applies. Mechanically created particles are generally greater than 1 micron in size and are often large enough to be seen with the naked eye. These particles can be observed as dust and grit. It can be difficult to make mechanically created particles less than 5 microns. In most instances, unless extreme approaches to grind particles are used, mechanically created particles tend to be much greater than a micron.

The Environmental Protection Agency and any and all regulatory agencies related thereto are very concerned about particles less than 2.5 microns.

Particle Size Defines Behavior

The size of a particle will dictate how the particle behaves. When discussing particle size and particle behavior there are two main competing properties: inertia and diffusion. These properties are defined by particle size which, as discussed above, is defined by particle origin.

Particles > 1 Micron in Diameter

Inertia is the ability of a particle to diverge from a gas streamline. Particles greater than 1 micron in diameter have significant inertial properties. This can be observed with gas, as gas turns the particle doesn’t turn and keeps going. These particles are easy to separate from a gas stream because of their tendency to have inertia. Generally, for particles greater than 1 micron in diameter, the particles can be collected by exploiting the inertial properties.

This can be seen in the inertial impaction image where there is an inertial particle in gas and another larger particle (the cross section of fiber). The gas wants to go around the bigger particle but the inertial particle that is entrained in the gas can and will separate from the streamline and crash into the bigger particle. That’s inertial impaction.

Particles < .3 Microns in Diameter

Particles less than 0.3 microns in diameter have significant diffusive properties and coagulate rapidly. The mean free path of air at atmospheric pressure is ~0.1 microns. Particles less than 0.2 microns can exhibit significant diffusion. Particles less than .05 microns (ultra fine particles) agglomerate very rapidly due to diffusion.

Brownian diffusion is the natural thermal behavior of gas molecules in a given volume. It is the characteristic random wiggling motion of small airborne particles in still air. This is caused by the constant barrage by surrounding gas molecules. Gas molecules bounce all around against each other depending on the temperature. When the temperature gets low enough, the gas molecules slow down and they stop. When this happens there is no diffusion at all.

Particles will do the same thing when they are a smaller size. With particles that are .3 microns or below significant diffusion can occur. That diffusive property can be exploited to provide away to collect the particles.

It is interesting to note that when it comes to ultrafine particles, the diffusive properties are so great that they can crash into each other. When this crash occurs the particles can stick together to form larger particles. When this occurs the diffusion stops.

Mid-Range Particles

What about particles between 0.3 and 1 microns in diameter? These mid-range particles are the worst because they are particles that are very difficult to collect or separate.

Mid-range particles have a number of undesirable characteristics. Particles between 0.3 and 1 microns in diameter have neither inertial nor diffusive properties, this makes them hard to collect. When particles are this size coagulation stops which means they are stable and difficult to collect.

Mid-range particles tend to be optically active and cause a lot of light extinction. Mid-range particles can cause smoke plumes. Smoke plumes can be observed from stacks as well from forest fires when visibility is impeded.

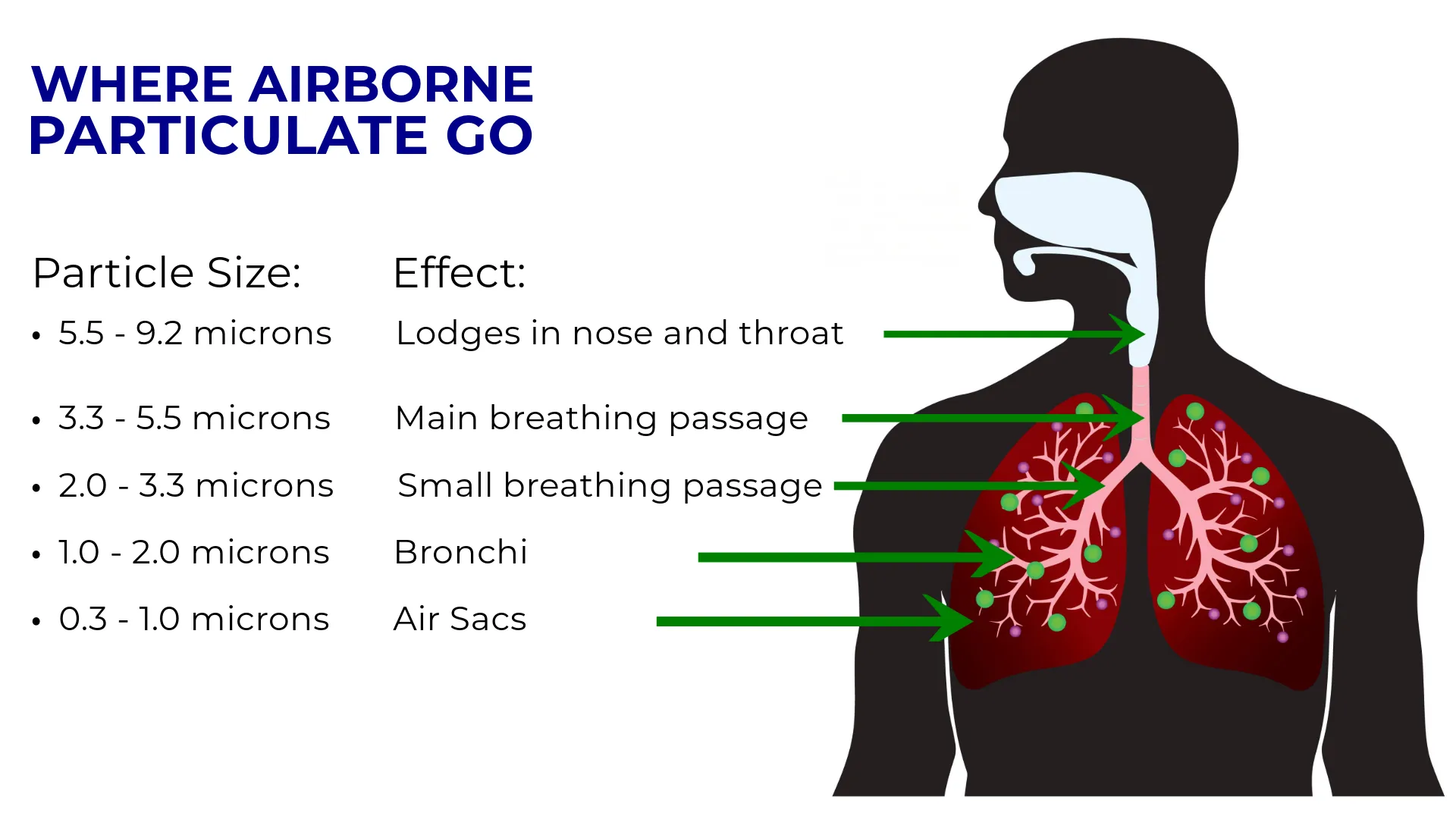

Beyond the negative optical aspects, mid-range particles are bad for health because mid-range particles can penetrate deep into the lungs. The chart on airborne particles provides some insight into how particle size can impact health. Mid-range particles penetrate the air sacs and can cause emphysema and cancer. The particles are dangerous because they go way down into the lung’s alveolar sacs where the lungs and the blood exchange oxygen and carbon dioxide during the process of breathing in and breathing out.

Biomass Fly Ash Particles

Biomass combustion can result in different kinds of particles. This can be from wood or agricultural products. When biomass is burned, generally speaking, the size distribution from these kinds of processes tends to look like the following chart.

When looking at the chart, there are two humps. This distribution is called the bimodal size distribution. The two humps are two modes.

The mode on the right represents the coarse particles that are seen from what generally is mechanical action. These are particles that are just simply entrained in the flue gas and go out. They’re created because they’re ground up particles. These particles totally dominate the mass concentration, the weight of the aerosol mix. These particles tend to be good news for collection. This is because the particles are big and coarse and easy to collect and it is most of the mass.

Unfortunately, it is not all good news when it comes to fly ash particles. The mode on the left is where all the air toxins are located. That’s where all the particles that are less than a micron are located. The mode on the left is where all the action is and what the EPA is focused on regulating.

Manganese is considered by the EPA to be air toxic. Where does it come from? It comes from manganese metal in the fly ash or in the wood originally in the biomass that melts and recondenses as a fine submicron aerosol because it’s a thermally created material.

Under MACT, there is a 0.037 lb/MM BTU limit. However, if the focus is on air pollution control equipment design it should not be limited to this mandate. It is better to design for air pollution control equipment that can achieve .020 lb/MM BTU. By aiming for something smaller you can make sure that you are going to meet the EPA requirements.

Next Up: Understanding Gases

This article has covered combustion basics including particle formation and behavior. This has included an overview of the influence of particle origin and size. Next up will be the final part of this three part series which will include a deeper look into gaseous emissions.

LDX Solutions помогает контролировать вредные выбросы

LDX Solutions is a proud partner of the wood products industry. We are a leading supplier of emission controls for wood products facilities worldwide. From inspection to installation and ongoing support, LDX Solutions ensures you are ready for the future. Contact LDX-Solutions today to learn more about our air pollution control solutions.