Particulate Matter Sampling

Much time and money are spent by field investigators trying to ensure that particulate matter sampling is conducted isokinetically, but with today’s tighter emission standards and better control equipment, it might be worthwhile to consider just how important isokinetic sampling is before conducting your next stack test.

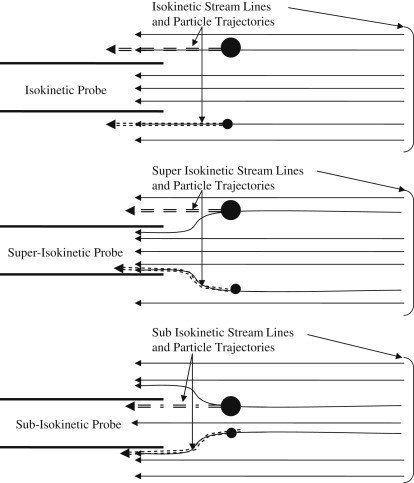

Isokinetic sampling techniques were developed to prevent skewed particulate concentration measurements due to the inertial effects of particles as they enter a sampling nozzle. Basically, the idea is to sample at the same velocity as the gas stream so that the streamlines in the vicinity of the nozzle are straight. Turns in the streamlines near the nozzle can cause heavier particles to miss the nozzle, thus skewing the measured value of concentration.

While the reasoning for isokinetic sampling is, in theory, correct, there are many instances where the effect of non-isokinetic sampling is negligible. Calculations show that a particle with an aerodynamic diameter of fewer than 2 microns has virtually no inertia at normal duct velocities and non-isokinetic sampling will have no effect on the measured concentration. Even sampling 4-micron diameter particles at velocities of 50% higher or lower than the gas stream will only cause a measurement error of 2 or 3 percent.

If you are sampling downstream of a control device and formal emissions or EPA-type testing is not dictated by law or contract, it may be worthwhile to consider eliminating the constraints of traditional isokinetic sampling. It will save time, money, and effort.